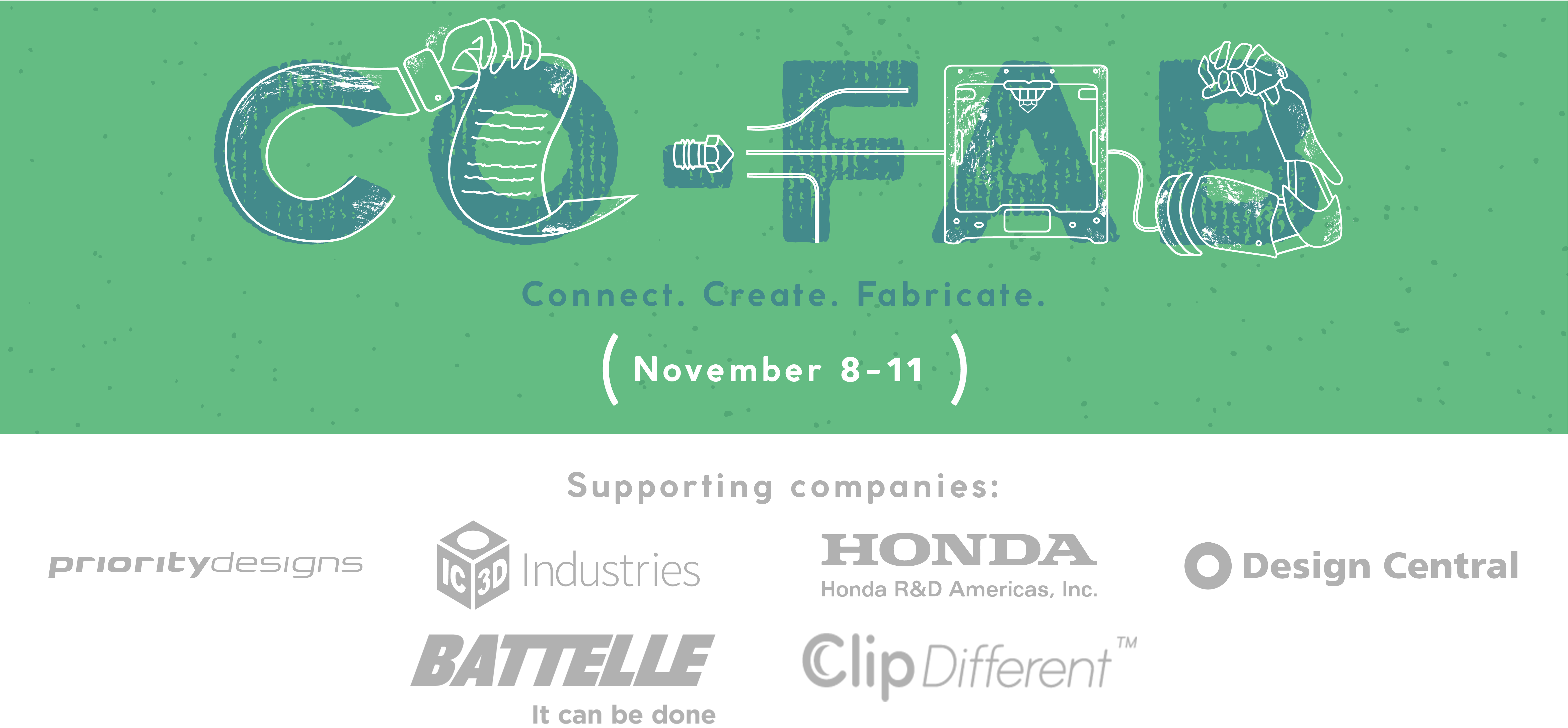

Form5 hosted its 3rd annual CO-FAB Workshop, kicking off in September and wrapping up over the workshop weekend in October. With its mission in mind, CO-FAB takes Form5’s empathetic and inclusive approach of innovating devices to a different level, sparking the imagination of those with limb differences.

CO-FAB is a six-week program that provides an opportunity for those with limb differences to co-create devices, empowering them to interact with their world and future more successfully. Applications for high school/college students, industry professionals, and recipients went live in May 2021, and Form5 selected participants in August.

Empowering Recipients:

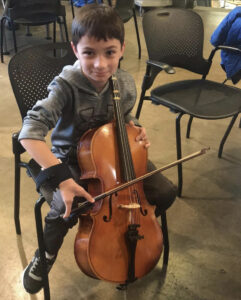

Three recipients with upper extremity limb differences were selected to participate in CO-FAB 2021: T’Kara (2.5), Grace (8), and Cali (14). All three girls love to be outdoors and have a passion for sports. Form5 provided each with a custom-application device at no cost that empowers them to embrace their future.

The 2021 Workshop:

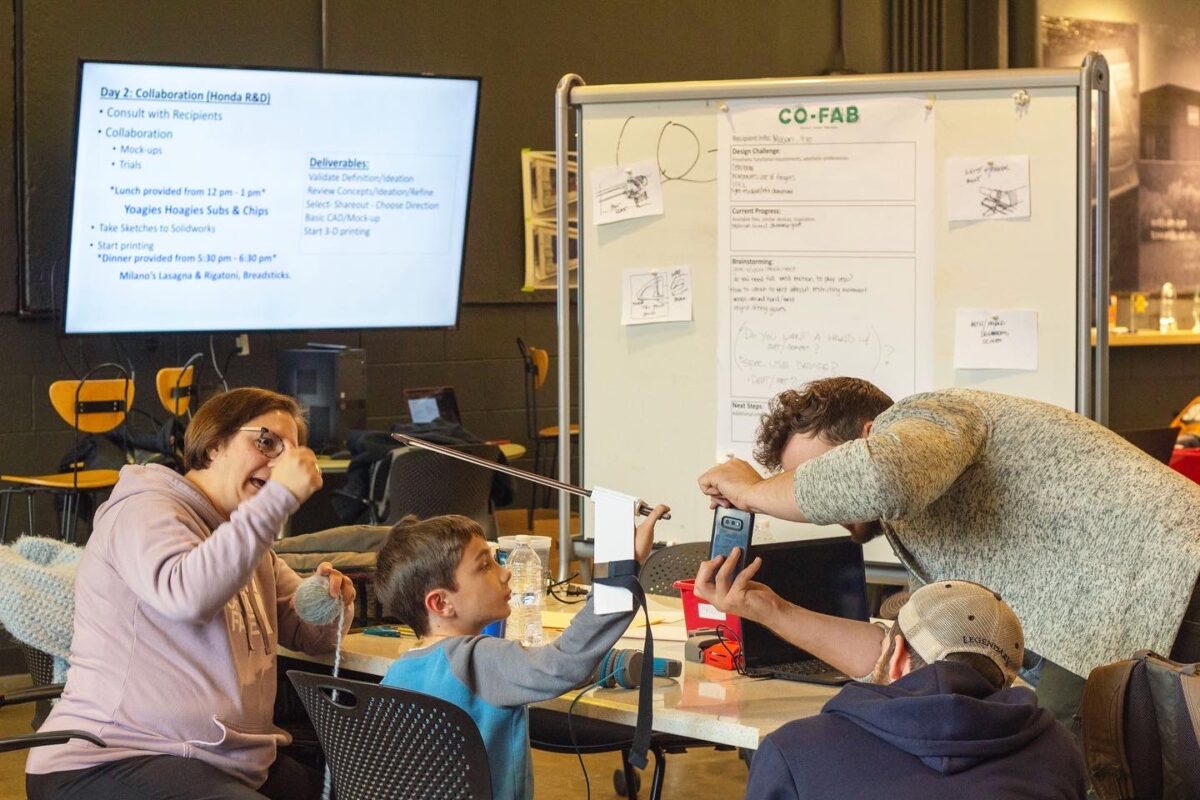

Through CO-FAB, each recipient gets paired with a team of students majoring in industrial design, engineering, and physical/occupational therapy to collaborate and fabricate life-changing devices. Form5 also engages employees from organizations like Honda R&D, AEP, Design Central, Priority Designs, and others to facilitate portions of the CO-FAB curriculum or mentor the teams. Erika Reeves, one of the team facilitators expressed that “CO-FAB changed her perspective on those with limb differences and on the process of creating impactful devices.”

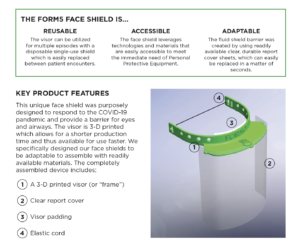

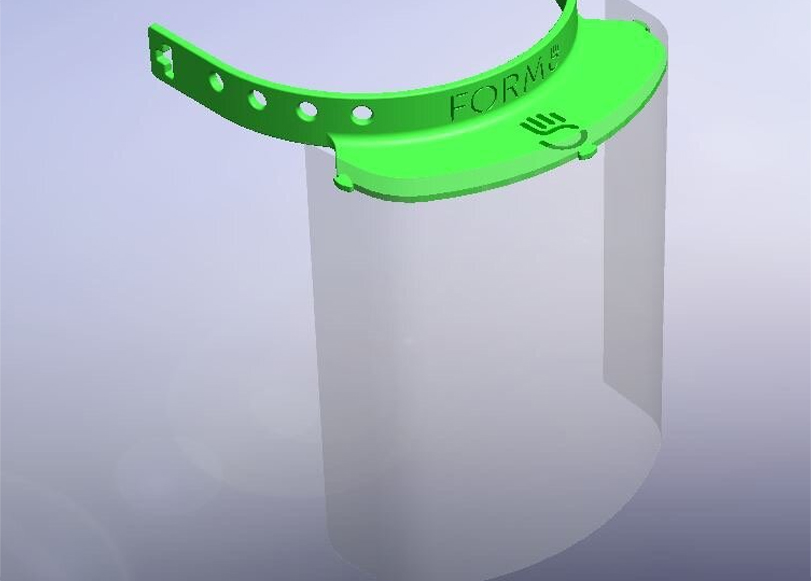

Form5 piloted its CO-FAB Curriculum this year, providing all participants with a robust, experiential learning opportunity. Form5’s CO-FAB Curriculum consists of modules rooted in STEM and Design Thinking, also touching on the importance of user-centric design and empathy. Form5’s CO-FAB Cohort of teams learned to use advanced technology to co-create custom-application devices, leveraging Form5’s Lab and 3-D printer fleet.

The CO-FAB Cohort met weekly from September 18th to October 24th:

Experiencing CO-FAB as a Student/Volunteer:

Form5 selected fourteen college students from the Ohio State University, Columbus College Art & Design, and Cleveland State University. One student participated as a part of his New Albany high school senior seminar project. With a dozen or so industry professionals donating their time and talent, mentoring project teams.

Jason Shuman, a 3rd-year student at Ohio State, shared that CO-FAB gave him newfound knowledge by “working with students of another craft that offer different perspectives and acquiring more technical skills.” Also, witnessing the overall effect that collaboration can have on the recipients he found rewarding.

From all the feedback received from volunteers and students, the most rewarding part of CO-FAB was seeing what can be accomplished through collaborative efforts and talents. Zack Alleman, a 2nd-year student at Ohio State, said “CO-FAB opened doors for learning new technological and social skills that [he] wouldn’t have had exposure to otherwise.”

Aarti Patel, another 2nd-year student from Ohio State, said that for her “the most rewarding part of the experience was seeing Grace comfortable with the device and gaining confidence in playing volleyball because of it.”

“After participating in the CO-FAB Workshop, I feel that I might be able to better empathize with people with limb differences. I was not only able to use my background in Biomedical Engineering to apply course content in a real-world application, but I was also able to make a connection with a young girl who shared my interests, and I was able to help her pursue those interests.” – Olivia Vick, a 4th-year student at Ohio State.

What CO-FAB means:

CO-FAB is essential to making devices that reflect the needs of the limb difference community as a whole. Through CO-FAB, Form5 is uniquely able to fill those needs with user-centric design and collaboration that is frequently unmet by traditional manufacturers. However, Form5’s impact extends beyond the limb difference community. Everyone involved in CO-FAB discovers a new sense of capability.

After each CO-FAB Workshop, the designs created are reviewed and refined by Form5’s Innovation and Technology Committee to explore the possibility of expanded product lines. Through these product lines, Form5 can make the life-changing innovations of each CO-FAB Workshop accessible to everyone with a similar limb difference.

Form5 is so thankful to its generous donors for supporting its mission and its volunteer designers, engineers, and change-makers alike that make the impact possible. Form5 has hosted three CO-FAB’s since its inaugural Workshop in 2019 and is inspired each year. Form5 plans to host two CO-FAB Workshops in 2022!